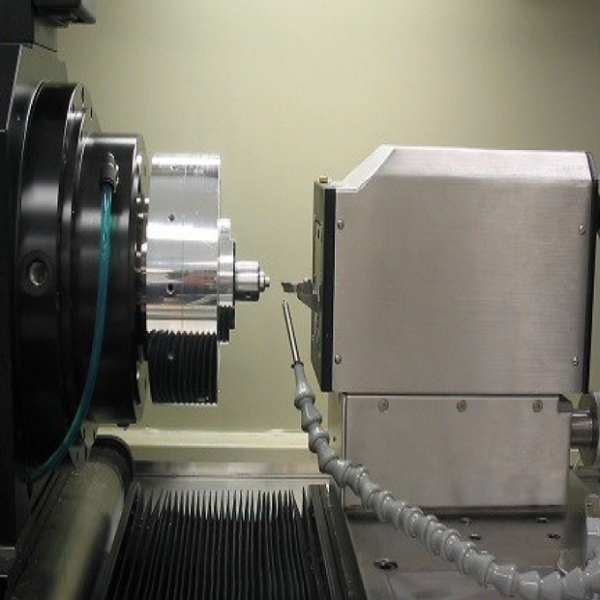

Nanotech – Diamond Turning Lathe – 250UPL, 450UPL

250UPL Compact Diamond Turning Lathe.

Simple to use and engineered for high productivity. Our latest generation of the most user friendly and compact ultra-precision CNC diamond turning lathe. Used for the rapid production of spherical & aspheric optical lenses, mirrors, mold inserts, freeform optics, and even mechanical components. If your application fits within a 350mm diameter window (with optional riser package), this machine may be the ideal solution for your ultra precision needs. Achieves both sub-nanometer level surface finishes and sub-micron form accuracies directly off the machine in a wide variety of materials.

450UPL Midsize Diamond Turning Lathe.

Only Nanotech offers a proven and established midsize ultra precision system. The 450UPLv2 is comfortably suitable for both single point diamond turning and deterministic micro-grinding of optical elements. Applications examples include the manufacture of components used in a wide variety of markets such as electro-optics, aerospace, defense, consumer electronics, bearing, and computer industries. As an ideal midsize option for our customers, the standard configuration of this popular machine model yields a 450mm diameter swing capacity, but increased swing capabilities are readily available upon request.

Optional C Rotary with Linear Y or Rotary B Axis

Expansion of the basic 2-axis system is simple. One can have up to 4 axes of continuous path motion via the addition of C & B or C & Y. The C-axis motion control of the work spindle enables toric, biconic, and other freeform surfaces to be machined “on-axis” via our Slow Slide Servo (S3) process. Our Air Bearing Rotary B or removable Oil Hydrostatic Vertical Linear Y-axis can be configured independently on the Z-axis carriage for future added flexibility.

Exclusive “Impact Resistant” Air Bearing Work Spindle

This ideal center mounted thrust plate design, engineered for both heavy loads and high throughput applications, includes the exclusive added durability benefits of Porous Graphite. Guaranteed motion accuracies of less than 12.5 nanometers throughout its 10,000 rpm speed range with total liquid cooling for long term thermal stability.

Technical Specifications

| Workpiece Capacity | 250UPL:300mm diameter x 200mm long (150mm diameter swing capability over the optional rotary B-Axis) 450UPL:450mm diameter x 300mm long – (200mm diameter swing capability over the optional rotary B-Axis) | |

|---|---|---|

| Base Structure | 250UPL:Natural Black Granite with integral slide channels and protective stainless steel apron 450UPL:Monolithic composite epoxy-granite, with integral coolant troughs and embedded carbon fiber reinforcement | |

| Vibration Isolation | Optimally located air isolation system. Optional Shear Damped air isolation system with Self Leveling | |

| Control System | Delta Tau 1GHz PowerPMAC Embedded Real-time 64-bit Linux Motion Controller with Nanotech’s NEW Windows 7 based HMI with a Touch / Swipe Gesture Interactive display. | |

| Programming Resolution | 0.01 nanometer linear / 0.0000001º rotary | |

| Workholding Spindle | Heavy Duty (Standard) | |

| Type | Exclusive HD impact resistant graphite air bearing with center mounted thrust face | |

| Speed Range | 50 to 10,000 rpm, bi-directional | |

| Swing Capacity | 250UPLV2:300mm 450UPLV2:450mm | |

| *For more data, please contact us | ||

Available Models

Key Features

V2 Series New Major Technology Advancements

· Impact Resistant Porous Graphite Air Bearing Work Spindle with less than 12.5nm motion error throughout entire speed range and 0.01 arc second C-axis resolution.

· Industry leading 8 picometer linear feedback resolution.

· Delta Tau Power PMAC Real-time 64-bit Motion Controller with 40,000 block lookahead for advanced trajectory calculations.

· Dedicated Ethernet / LAN connection allows real-time monitoring and control of the machine by the factory (or the customer) to remotely evaluate all control functions for instantaneous diagnosis and troubleshooting of any control or programming problems.

· NanoSMART ™ – Industry’s First Touch / Swipe Gesture Based Interactive HMI with numerous new value added features including ability to process up to 5GB program file sizes.

NanoSMART® Windows Based Interactive HMI Control System

Featuring a high speed 64 bit Delta Tau PowerPMAC, this motion controller is the industry’s first touch / swipe gesture “smart” screen display. Three customizable 22″ wide screens are accessible by swiping left or right from the main screen. Now you have the option to easily create and save your own custom user friendly interface screens to satisfy a particular individual’s preference or a specific application. 5GB program file sizes, 4X faster processing speeds, remote diagnostics and an industry leading 8 picometer feedback resolution combine to make the new Nanotech 450UPLv2 the most operator friendly high performance mid-size diamond turning system available.

Contact Us

| Beijing 26th Floor, West Tower, Hanwei Plaza No.7 Guanghua Road, Chaoyang District, Beijing TEL: 010-6561 3988 FAX: 010-6561 0278 http://dksh-machinery.com | Shanghai Room Unit 605-607, Build 2, Xinglian Building, No.1535 Hongmei Road, Xuhui District, Shanghai TEL: 021-5383 8811 FAX: 021-3367 8466 http://dksh-machinery.com | Chengdu Room 802, 8/F, Tower 1, Central Plaza No.8 Shuncheng Street, Chengdu TEL: 028-8676 1111 FAX: 028-8676 1122 http://dksh-machinery.com |

| Guangzhou Room 1213-1215, 12/F Jie Tai Plaza, 218-222 Zhongshan Road ,Guangzhou TEL: 020-8132 0662 FAX: 020-8132 0663 http://dksh-machinery.com | Xi’an B-4-H, K.I.Tower, No.1 Xihuamen, Xi’an TEL: 029-8833 7412 FAX: 029-8833 7415 http://dksh-machinery.com | Hongkong 23/F, Tower A, Southmark, 11 Yip Hing Street, Wong Chuk Hang, Hong Kong TEL: 00852-2880 9808 FAX: 00852-2369 1042 http://dksh-machinery.com |

Key Industries

- Aerospace

- Automotive

- Die and Mould

- Electronics

- Machinery and Manufacturing

- Medical

- Mining and Minerals

- Oil and Gas

- Semiconductor, Solar and Electronics

- Shipbuilding

More Products

Moore Nanotechnology Systems was founded in Keene, NH in 1997 as a stand-alone subsidiary of Moore Tool Company. We are…