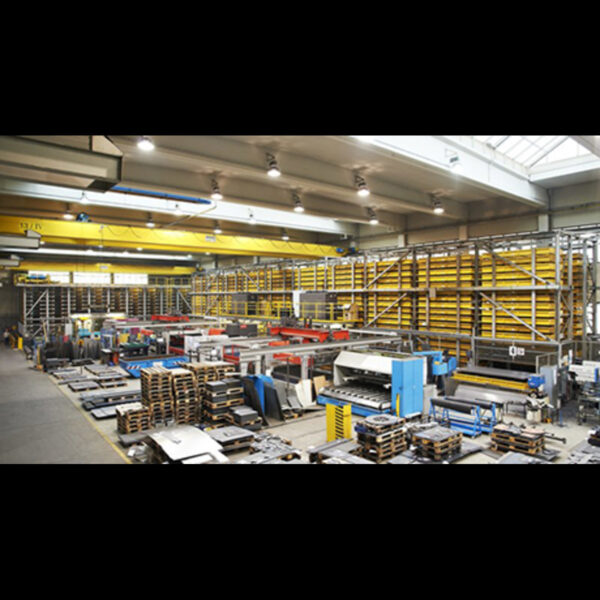

Remmert – RetroFit

Perfect for anyone looking for a storage modernisation suiting their requirements. Uncomplicated, quick, client-specific. We make your storage system fit for use – quick and uncomplicated. Our expertise: the optimisation of production and intralogistical processes. To allow you to focus on your key skills, we complete your RetroFit during operation. As Remmert develops RetroFit concepts in a task-based and manufacturer-independent way, the modernisation of storage systems from other manufacturers is also easy to achieve. Solutions for complex problems all in one place. Together with you, we make every RetroFit concept custom to meet your requirements.

The Remmert RetroFit services

- Replacing non-functioning or old components

- Replenishing the replacement parts available

- Providing current technology, e.g, migration from S5 to S7

- Interface optimisation

- Updating or integrating a WMS (warehouse management system) and coupling an ERP system

- Optimised storage logistical overall concept

- New drive and drive concepts e.g. for your lifting and driving tools

- Optimised material and information flow concepts

- Current concepts for storage and retrieval machines and safety

- Expansion of automation

- Expansions for process visualisation

- Connection of processing machines

Key Features

RetroFit

- Low downtimes

- Increasing the level of automation

- Large energy savings

- Low personal intensity and low maintenance costs

- Lowering of downtimes by at least 20%

- Higher storage availability of at least 98%

- Increase in productivity by at least 30%

More Products

“We make material flow.” With this statement the material handling expert Remmert addresses the metal working industry as well as…