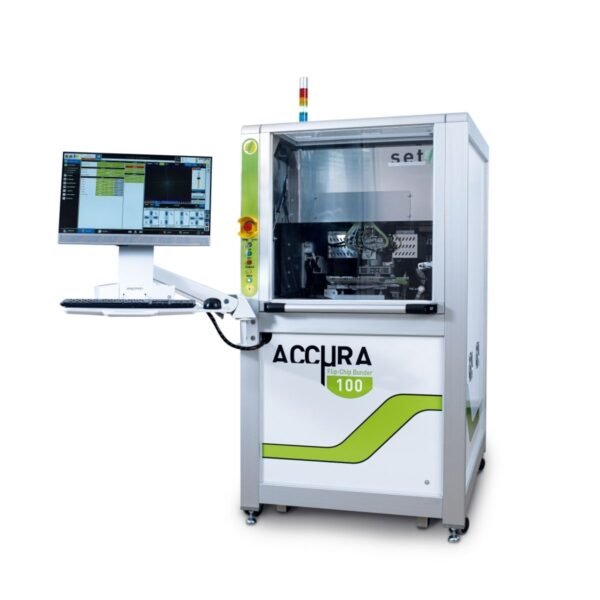

SET – ACCµRA100

The ACCµRA100 is a flip-chip bonder that allows ± 0.5 µm accuracy. Motorized axes guarantee a high repeatability of your process. Its flexibility makes it ideal for developing a wide range of applications. ACCµRA100 combines...

The ACCµRA100 is a flip-chip bonder that allows ± 0.5 µm accuracy. Motorized axes guarantee a high repeatability of your process. Its flexibility makes it ideal for developing a wide range of applications. ACCµRA100 combines high precision, accessibility and cost-effectiveness. It is the perfect equipment for universities and R&D institutes.

Applications

- Micro assembly

- Laser diode, laser bar

- VCSEL, photo diode

- LED

- Flip-chip bonding, die bonding

- Chip-to-chip, chip-to-substrate bonding

- MOEMS, MEMS, MCM packaging…

- 3D packaging

- Nanoimprinting (UV NIL and Hot Embossing)

Industries

- Semiconductors

- Memory

- Optoelectronics and Silicon Photonics

- Micro LEDs Displays

- Quantum Computing